Fiber Laser Cutting in the Aerospace Industry

Get Latest Price| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Qingdao Port |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Qingdao Port |

Model No.: XL3015C

Brand: XUANLIN

Application: Laser Cutting

Applied Material: Metal

Old And New: New

Laser Type: Fiber Laser

Cutting Area: Other

Whether CNC: Yes

Cooling Method: Water Cooling

Place Of Origin: China

Certification: Ce, Iso, Gs

Industrial Laser Brand: Ipg

Industrial Laser Head Brand: Worthing

Servo Motor Brand: Yaskawa

Linear Guide Brand: Hiwin

Laser Machine Control System Brand: Cypcut

Warranty Period: 3 Years

Out-of-warranty Service: Video Technical Support, Spare Parts, Field Maintenance And Repair Service

Applicable Industry: Machinery Repair Shops, Farms, Construction Works, Energy &Amp; Mining, Food &Amp; Beverage Shops, Advertising Company

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 3 Months

| Selling Units | : | Set/Sets |

| Package Type | : | wooden package |

Sheet Metal Fiber Laser Cutting

Laser Cutting is a sheet metal processing that laser beam radars on the processing material. Laser Machine works by directing the output of a high-power laser most commonly through optics. The laser beam can be divided into solid state and un-solid state

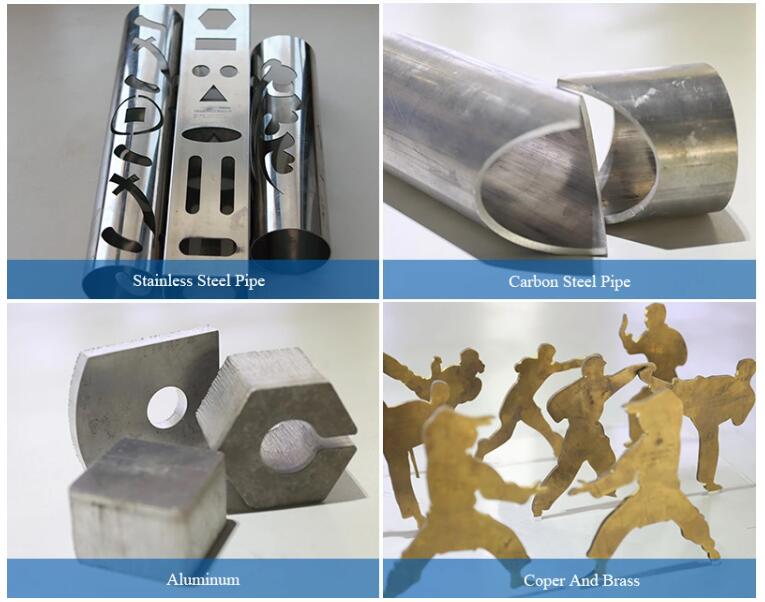

XUANLIN cnc laser machine is one of China’s leading companies in the field of process-to-order manufacture of sheet metal products, and over the years it has grown into a major centre specialising in a variety of materials and processes: today we have 2 laser systems with automated loading and unloading systems.The Sheet Metal Laser Cutting division of XUANLIN CNC can process stainless steel sheets and, thanks to the innovative laser technology, it can also process non-ferrous materials, such as aluminium, copper and brass.

| Machine model | XL3015C |

| Laser power | 1000W 1500W 2000W 3000W(Optional) |

| Dimensions | 4440* 2500*1860mm |

| Working area | 3000mm x 1500mm |

| Repeat positioning accuracy | ±0.02mm |

| Maximum speed | 80m/min |

| Max. acceleration | 1.0G |

| Voltage and frequency | 380V 50Hz/60Hz/60A |

Applications

Laser cutting is a process where a material is cut through the use of a laser beam. This can be for small & fine materials or materials with a much greater level of thickness (e.g. metal sheets). The process simply involves the use of a focused laser beam (e.g. pulsed or continuous wave) to cut a wide range of materials to a high level of accuracy, using a process, which is highly repeatable.

The laser beam can easily be programmed to precision cut a diverse range of thicknesses and materials (e.g. metals (including reflective metals such as copper, silver and aluminium) – brass, tungsten, steel, pewter and titanium etc.), gemstones (e.g. diamonds), ceramics, graphic composites, silicon and many types of plastics.

Even the most complex, awkward and intricate of shapes can be accurately cut through a Fiber Laser as the user has total control over the beam intensity, duration and heat input. Laser cutting has some similarities to other laser-based processes such as engraving and drilling, which also use a focused laser beam to effectively make designed cuts into a material.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.