Low Power Fast Cutting of Mild Steel

Get Latest Price| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Qingdao Port |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Qingdao Port |

Model No.: XL3015GAR

Brand: XUANLIN

Application: Laser Cutting

Applied Material: Metal

Old And New: New

Laser Type: Fiber Laser

Cutting Area: Other

Support Graphic Format: Ai, Plt, Dxf

Whether CNC: Yes

Cooling Method: Water Cooling

Place Of Origin: China

Certification: Ce, Iso, Gs

Industrial Laser Brand: Ipg

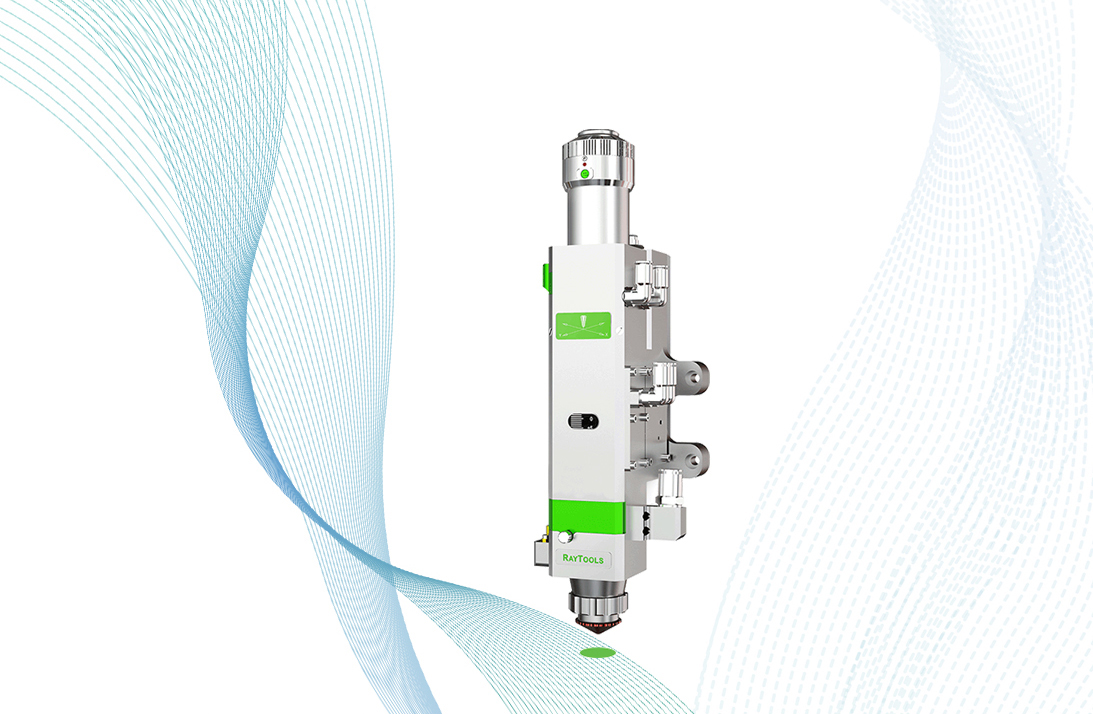

Industrial Laser Head Brand: Raytools

Servo Motor Brand: Yaskawa

Linear Guide Brand: Hiwin

Laser Machine Control System Brand: Cypcut

Warranty Period: 3 Years

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Applicable Industry: Building Material Shops, Machinery Repair Shops, Advertising Company

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 3 Years

| Selling Units | : | Set/Sets |

| Package Type | : | wooden package |

H Beam Laser Cutting Third Parties

Sheet Metal Laser Cutting is typically used to cut mild and stainless steels, copper, brass and aluminium. Some uses include components, structural members, and battery electrodes. The process can also cut reflective metals. It is used extensively in the automotive , aerospace, and engineering industries. Laser Cutting is an established industrial process for fine tolerance cutting of metals, to produce accurate detailed shapes with smooth edges, generally in thin sections,such as Tube Laser Cutting,H beam Laser Cutter, Sheet Metal Laser Cutting. XUANLIN’s Cnc Laser may be used to cut a variety of metals including mild steel, copper, aluminium and brass. Modulation of the Laser Machine power can be used to improve the control heat input and cut quality. Fine tolerance cutting has been used here to produce combs in 1mm stainless steel. This process required Nitrogen gas-assistance for dross-free laser tube cutter.

XL3015CR Fiber Laser Cutting Machine can not only cut metal plates, but also metal pipes. It has many uses and can save the space of more than 50%, which effectively improve productivity.

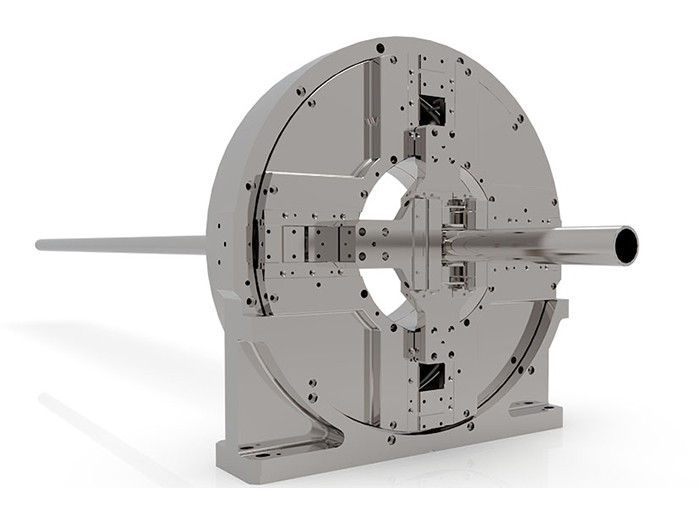

It adopts an electric clamp design on both sides and it can modulate the center automatically. The diagonal adjustable range is 20-200mm.

It employs intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

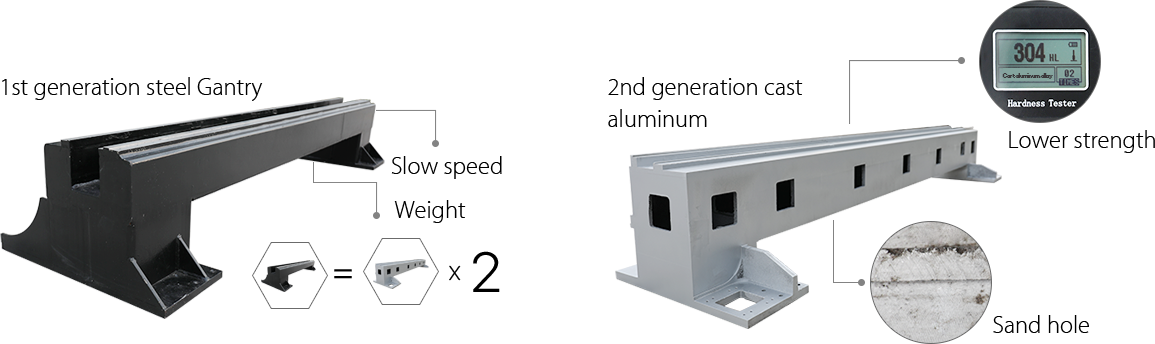

The internal structure of the bed adopts the aircraft metal honeycomb structure, which is welded by a number of rectangular tubes. Stiffeners are arranged inside the tubes to increase the strength and tensile strength of the bed, it also increases the resistance and stability of the guide rail so as to effectively avoid the deformation of the bed.

| Machine model | XL3015CR |

| Laser power | 1000W 2000W 3000W 4000W 6000W 8000W(Optional) |

| Dimensions | 4600*2450*1700mm |

| Working area | 3000mm x 1500mm |

| Repeat positioning accuracy | ±0.02mm |

| Maximum speed | 120m/min |

| Maximum acceleration | 1.5G |

| Specified voltage and frequency | 380V/50Hz/60Hz/60A |

Metal laser cutting is typically used to cut mild and stainless steels, copper, brass and aluminium. Some uses include components, structural members, and battery electrodes. The process can also cut reflective metals. It is used extensively in the automotive , aerospace, and engineering industries.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.